8 Easy Facts About Motorcycle Parts New Zealand Specialists Explained

Table of ContentsThe Buzz on Motorcycle Parts New Zealand SpecialistsHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking AboutSome Known Factual Statements About Motorcycle Parts New Zealand Specialists All about Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists - QuestionsMotorcycle Parts New Zealand Specialists Can Be Fun For AnyoneWhat Does Motorcycle Parts New Zealand Specialists Mean?

So, get to out to one of our professionals today.CNC machining technology is promptly ending up being the prime focus of numerous various production procedures around the globe as a direct outcome of its numerous advantages over other methods. In addition, the industries that make bikes have hopped on board with this fad. One of the most ingenious companies are currently developing their engine parts and wheels utilizing machining methods initially developed for motorbike components.

You might be asking yourself why we use. Currently that we have your attention let us clarify the rationale behind this modern-day development in the bike manufacturing market.

Examine This Report on Motorcycle Parts New Zealand Specialists

In enhancement, you have total control over the look of the elements, even down to the minute details. Sometimes, motorcyclists might choose to spruce up their ride by mounting aftermarket components or modifying the bike's remodeling.

The Buzz on Motorcycle Parts New Zealand Specialists

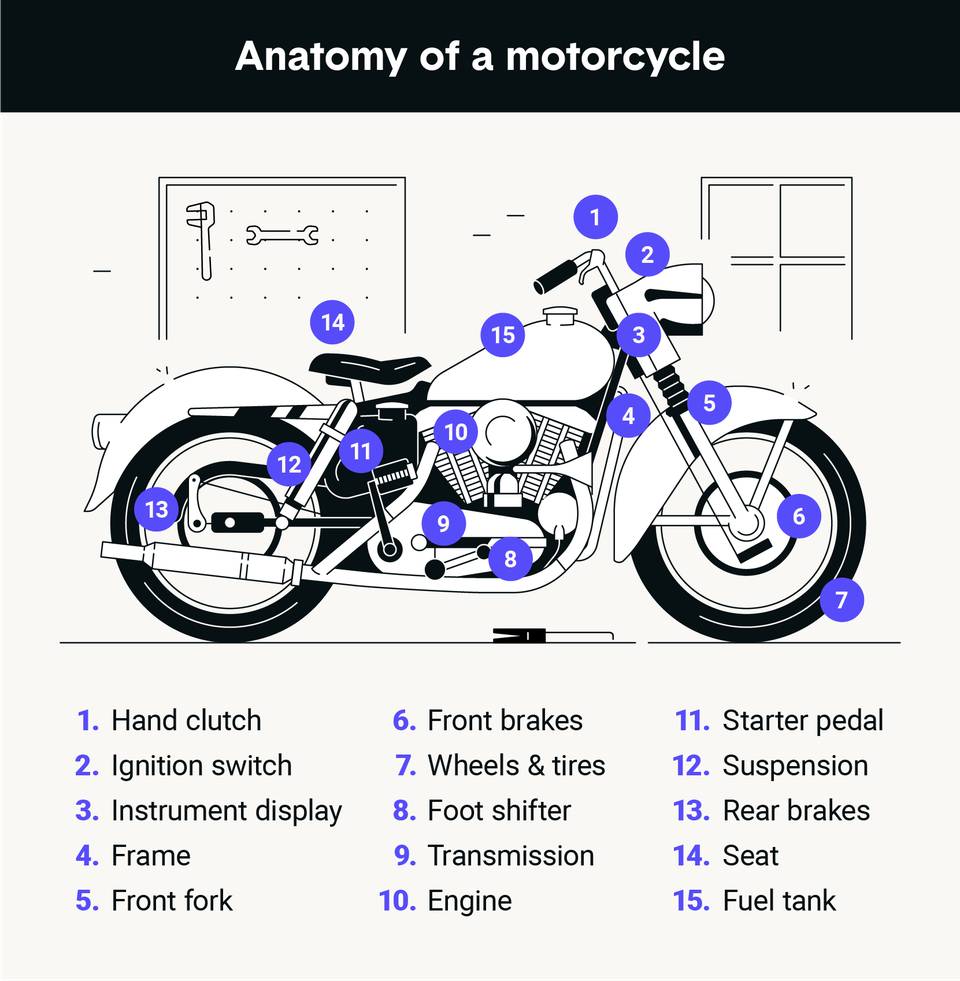

CNC machining might be utilized to make mostly all of a motorcycle's steel and plastic elements. To continue, we'll discuss several machined parts for bikes. As opposed to those on cars, wheels on bikes often tend to be a lot more noticeable. Therefore, the bike's appearances may be improved with the suitable personalization of these wheels.

When customizing the wheels, the disks are where the emphasis needs to be. Most of them are made out of aluminum. Light weight aluminum alloys are popular for the superior machining abilities that they have. Milling treatments are used to obtain the preferred level of wheel personalization. Another element of the motorbike that may be individualized is the tires.

3 Easy Facts About Motorcycle Parts New Zealand Specialists Shown

When it pertains to a lorry (or a motorcycle), the most crucial component is the engine. Numerous people point to it as the "heart" of the automobile. On the other hand, the camshaft, the cylinder head, and the pistons often tend to be intricate and call for styles with a high degree of accuracy.

Use only top notch items, nonetheless, given that these lights are crucial for the safety and security of motorcyclists and various other motorists or people on the roadway, especially at evening. Bike fronts lights have 3 main components: the bulb, or light source, the lens, and the real estate.

Milling procedures with a flawless surface would result in the lenses having a reflective quality that resembles that of a mirror. The cover, on the various other hand, is not composed of vulnerable materials; rather, it is built out of tough polymers that can be machined right into even more intricate patterns.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

Motorbike suppliers usually cast these components, yet just for the manufacturing of bespoke parts. Machining on five axes in today's world is the methods by which any design form might be understood.

The success of the process is contingent on the mill cutters' ability to calculate refined and difficult angles precisely. Choose Runsom for your personalized bike parts! We have the ability to fabricate complicated and elegant elements making your bike unparalleled. A lot of are crafted from aluminum or steel alloys, each of which has its uses and benefits.

Here are a few examples of steels typically used in motorcycle component machining. Aluminum is the key Read More Here material made use of by business concentrating on creating custom motorbike parts to create many of these components. In the past, we would certainly construct our engines out of cast iron. On the other hand, light weight aluminum is swiftly becoming the product of selection, partially as a result of the fact that it is extra lightweight.

Zinc describes another steel that is very light in weight and has terrific machining top qualities as a result of its high mechanical strength. This material may be created right into practically any shape and preserves its dimensions well. Also mission-critical elements that require a high level of accuracy might gain from their usage.

Top Guidelines Of Motorcycle Parts New Zealand Specialists

One more steel that sees heavy usage in the manufacturing of CNC-customized parts is magnesium. It is amongst the lightest steels that are now easily accessible and has superb machinability features and strength appropriate with its low weight. One of the disadvantages of magnesium is that its dirt might easily capture fire.

Due to its remarkable machinability and weldability, stainless-steel is an alloy that is specifically fit for CNC processes. They have fantastic rust resistance and a high visual appeal. Their most usual usage in generating different motorbike elements is bolts, such as screws and bolts. Their reduced susceptibility to oxidation and rust makes them ideal for this usage.

Motorcycle Parts New Zealand Specialists for Beginners

It appears that CNC turning and milling are the fundamental processes. In enhancement, it requires maintaining bars of product, most frequently plastic or metal, in placement and then turning a reducing tool to eliminate areas of the material as the product is turned.

These approaches are just as crucial and produce components see this website with high precision and constant high quality. The processes aid improve the total top quality of the machined motorbike parts.

Motorcycle Parts New Zealand Specialists - The Facts